¶ Contributions

FusFun™ ToughPETG-HF: High-Speed Toughened PETG for FDM 3D Printing

| Submit a Contribution | Any useful tips, knowledge, experiences, and more that you’d like to share. | Send to [email protected] |

| Correction | If you find any errors or inaccuracies, including typos, descriptions, technical terms, solutions, and more. | Send to [email protected] |

| Copyright | Any copyright-related issues. | Send to [email protected] |

¶ Product Highlights & Drawbacks

|

Application Scenarios |

ToughPETG-HF is ideal for industrial manufacturing, automotive, electronics, medical applications, sports & outdoor gear, and food packaging. It is tougher and more impact-resistant than standard PETG and offers enhanced weather resistance and structural strength, with improved ease of high-speed printing. | |||

| Highlights | High Impact Resistance | FusRock®'s toughening technology enhances ToughPETG-HF's notched impact strength to more than twice that of regular PETG, while maintaining strong Z-axis layer bonding. | ||

| Dimensional Stability | Low warping and shrinkage with excellent interlayer adhesion. It deforms less than ABS and nylon when printing large objects. | |||

| High-Speed Printing | Exceptional material flowability allows for excellent print quality, even at extreme speeds up to 400mm/s. | |||

|

Drawbacks |

Strong Bed Adhesion | ToughPETG-HF adheres firmly to PC build plates. For large bottom surfaces, increase the initial layer height. | ||

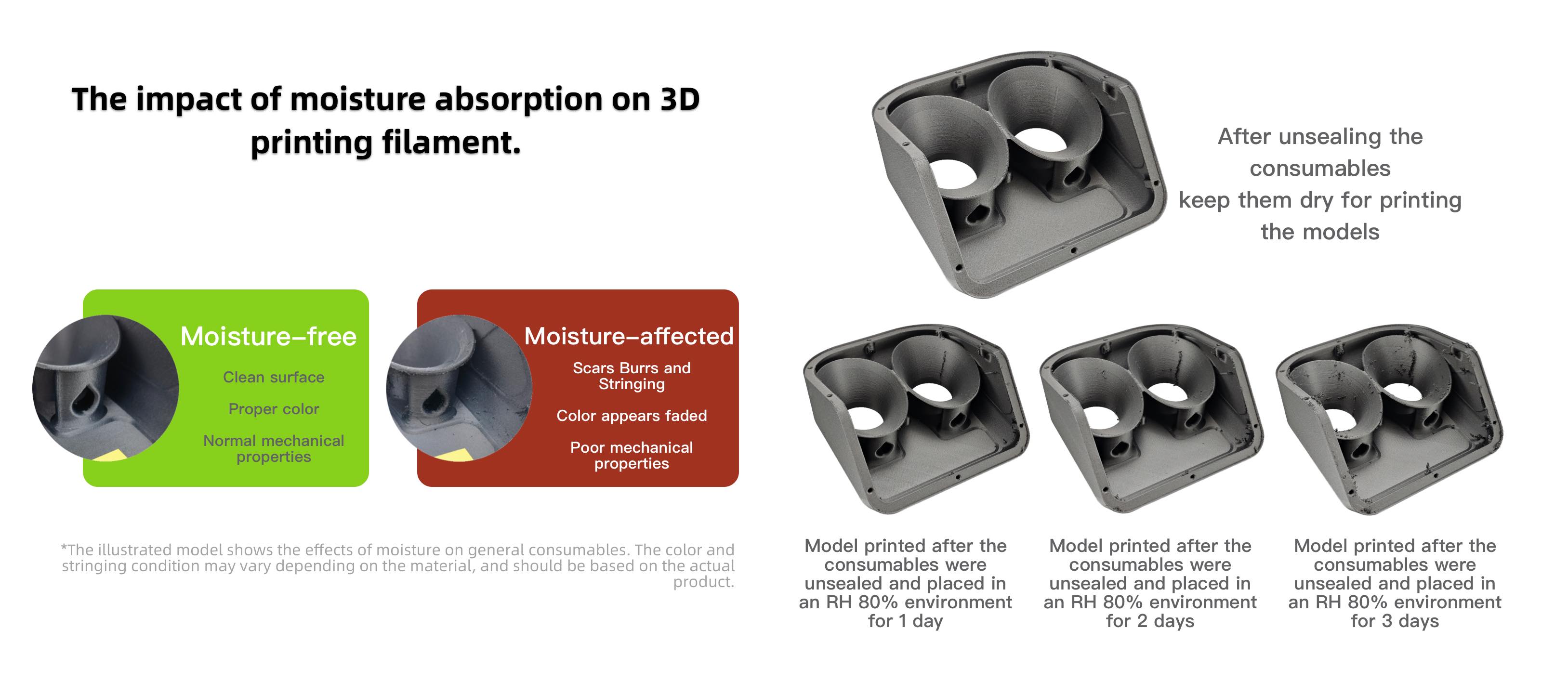

| Nozzle Adhesion & Stringing | High flowability can lead to nozzle adhesion, stringing, and dripping. Keeping the filament dry and fine-tuning retraction, temperature, cooling, and nozzle selection can reduce these issues. | |||

| Moisture Sensitivity | Must be stored in a sealed container with desiccants to prevent degradation of print quality. | |||

¶ 3D Printer Requirements & Filament Storage Guidelines

| Nozzle Material |

Recommended: Brass Nozzle (0.2-1.0 mm) Stainless steel or hardened steel nozzles are also suitable. |

| Nozzle Heater Block Length |

≥8mm heating zone recommended. Printer must support temperatures of 240-260°C. |

| Seal the box |

No enclosure required

|

| Warehouse temperature auxiliary heating | No enclosure required |

| Heated Bed Requirements | Heated bed required: Temperature 100-110°C |

| Recommended bed surfaces | Glass, PEI sheet, or PVP glue coating. |

| Instructions for applying glue | It is recommended to apply PVP glue to print large models or models with small contact surfaces. |

| Placement of consumables |

Direct plug-in printing is not recommended (moisture-proof consumables are damp, resulting in drawing and printing failure, and the printing effect is poor). It is recommended to print in a moisture-proof box with bearings. When you really need plug-in printing, please pay attention to whether it will interfere with the material plate when plug-in some devices, resulting in printing extrusion obstruction and making the material output not smooth. |

| Auxiliary equipment (AMS/AMS2, Lite, etc.) | Support, regularly replace the moisture-proof agent or check the performance humidity, and do a good job of moisture-proofing. |

| Be damp-proof |

* After opening for the first time, immediately put it in the moisture-proof box for use, and control the humidity below 15%; after moisture in the later stage and printing quality decline, you can refer to the Wiki drying method for drying consumables. * Be sure to read the following drying notes in detail before drying! Put it in the 70-80℃ oven and dry it for 4-6h! |

| Feeding pipe method (angle, bending, etc.) | Ensure smooth feeding |

¶ Print setting parameters (slicing software setting recommended parameters)

| Recommended nozzle diameter and nozzle material | The printing difficulty is relatively moderate. Be sure to keep it dry and the feeding smooth. It is recommended to use a copper nozzle. |

| Nozzle temperature | 230-260 °C |

| Build plate temperature | 70-80 ℃ |

| Cooling fan speed | 0%-50% |

| Retraction distance | 0.4-5 mm |

| Retraction speed | 30-60 mm/s |

| Print speed | 30-300 mm/s |

| Volumetric flow rate | 28mm³/s |

| Test traffic magnification | 0.95 (for testing, it is actually recommended to select the flow test according to the requirements of the machine), it is recommended to turn off the automatic flow calibration function |

| Test printing temperature | 260 ℃ (only for testing the recommended printing temperature) |

| K value | The default of Tuozhu equipment is 0.02. Other equipment refers to the manufacturer's recommended parameters. Please calibrate the value and then change the manufacturer's recommended value (when the deviation between the calibrated value and the manufacturer's recommended value is too large, please consider recalibration test or contact us for consultation). The K value will affect the quality of the printing product and the success or failure of printing. |

| Recommended parameters of high-speed mode | The nozzle is 260-280℃, the speed is 200-300mm/s, and the consumables are kept dry and put in the drying box. |

¶ After printing, rehealing and static requirements

| Annealing requirements | Meaningless |

| Static requirements | N/A |

| Others | To better preserve long-unused consumables, place them back into the original aluminum foil packaging and add desiccants such as silica gel packs or molecular sieves. Then, vacuum-seal the package and store it in a cool place away from direct sunlight to ensure the consumables remain in optimal condition. |

¶ Recommended supporting materials

| Supporting materials | / |

¶ Print parameters (configuration file) download

| Equipment model | Nozzle diameter | Download | File making and slicing software | Date |

| BambuLab X1C | 0.4mm | /fr25/toughpetg-hf/fusrock_toughpetg-hf_x1c_20250514.3mf | Bambulab Studio 1.9.7.52 | 20250102 |

¶ Moisture-proof requirements for printing and consumables

| How to place it when printing |

The recommended placement scheme is shown in the figure below:  Use it with a moisture-proof box; be sure to ensure smooth feeding. It is recommended to put it in a moisture-proof box with a bearing and use a Teflon tube to send it for printing. |

Direct plug-in printing is not recommended (moisture-proof consumables are caused by moisture, resulting in drawing and printing failure, and the printing effect is poor) When you really need plug-in printing, please pay attention to whether it will interfere with the material plate when plug-in some equipment, resulting in printing extrusion being blocked and the material output is not smooth. ( Solution)

|

| Moisture-proof requirements |

1. Replace desiccants promptly: To avoid the situation where the desiccant has absorbed moisture but the hygrometer shows no change, make sure to replace the desiccants in a timely manner. 2. Ensure proper moisture protection during printing: Always store materials in a moisture-proof box during printing. Do not use commercially available heated moisture-proof boxes that heat the material while printing. This can accelerate material aging and may lead to further moisture absorption if water vapor cannot escape. 3. For printing with AMS/AMS2, be sure to monitor the humidity display status and replace the desiccant when needed. 4. Dry materials promptly if they become humid: If the material has absorbed moisture, ensure it is dried immediately to restore its optimal condition. |

|

¶ Material (Moisture Protection) Storage Requirements

| Short-term Non-use | 1. Place the material in a sealed moisture-proof box or a simple vacuum-sealed bag to avoid direct sunlight. | |

| Long-term Moisture Protection | 1. After placing the material in its original aluminum foil bag, expel the air from the aluminum foil bag (if possible, place a desiccant inside, such as silica gel). Then, place the bag in a vacuum-seal food preservation bag, and vacuum seal it. Store it in a cool, dry place, away from direct sunlight. | |

¶ Material Properties

| Property | Testing method | Typical value |

|---|---|---|

|

Density |

ISO 1183 |

1.27 g/cm³ |

|

Melt index |

220°C, 2.16kg |

7 g/10min |

|

Thermal Properties |

Testing method |

Typical value |

|

Glass transition temperature |

ISO 11357 |

80 ℃ |

|

Determination of temperature |

ISO 75 Method A 1.80MPa |

65 ℃ |

|

ISO 75 Method B 0.45MPa |

70 ℃ |

|

|

The heat deflection temperature (HDT) is generally related to the environmental pressure or load the material is subjected to. Therefore, according to ASTM D648 or ISO 75-1, -2 standards, the material is tested under two pressures: 0.45 MPa (simulating no applied pressure load) and 1.80 MPa (simulating an applied pressure load). This allows for a better description of the material’s thermodynamic performance. Typically, the HDT measured at 0.45 MPa will be higher than the HDT measured at 1.80 MPa. |

||

| Mechanical Properties |

Testing method |

Typical value |

|

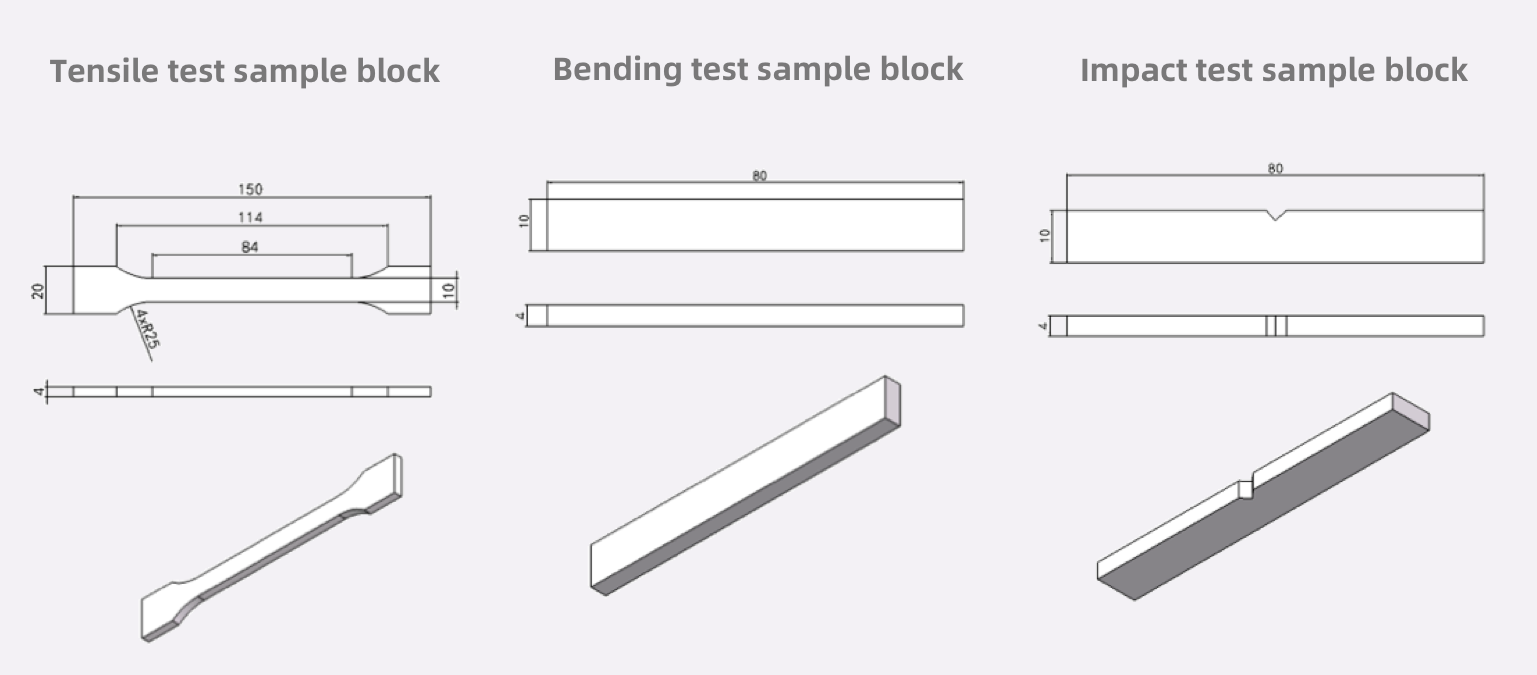

Tensile yield strength(X-Y) |

ISO 527 |

44.23 ± 0.64 MPa |

|

Yield elongation(X-Y) |

4.19 ± 0.06 % |

|

|

Young's modulus(X-Y) |

1821.82 ± 49.41 MPa |

|

|

Tensile breaking strength(X-Y) |

21.92 ± 3.98 MPa |

|

|

Elongation at break(X-Y) |

14.04 ± 7.77 % |

|

|

Tensile breaking strength(Z) |

ISO 527 |

42.70 ± 0.51 MPa |

| Young's modulus(Z |

1955.67 ± 179.30 MPa |

|

|

Elongation at break(Z) |

4.51 ± 0.82 % |

|

|

Bending strength(X-Y) |

ISO 178 |

71.40 ± 0.74 MPa |

|

Bending modulus(X-Y) |

1895.07 ± 36.19 MPa |

|

|

Impact performance |

Testing method |

Typical value |

|

Charpy impact strength(X-Y) |

ISO 179 |

16.39 ± 2.16 KJ/㎡ |

|

Specimens printed under the following conditions: Nozzle size 0.4mm,Nozzle temp 240°C, Bed temp 80°C, Print speed 45mm/s, Infill 100%, Infill angle ±45° |

||

|

||

Interpretation of Common Material Performance Parameters

¶ Material Moisture Treatment Plan and Methods

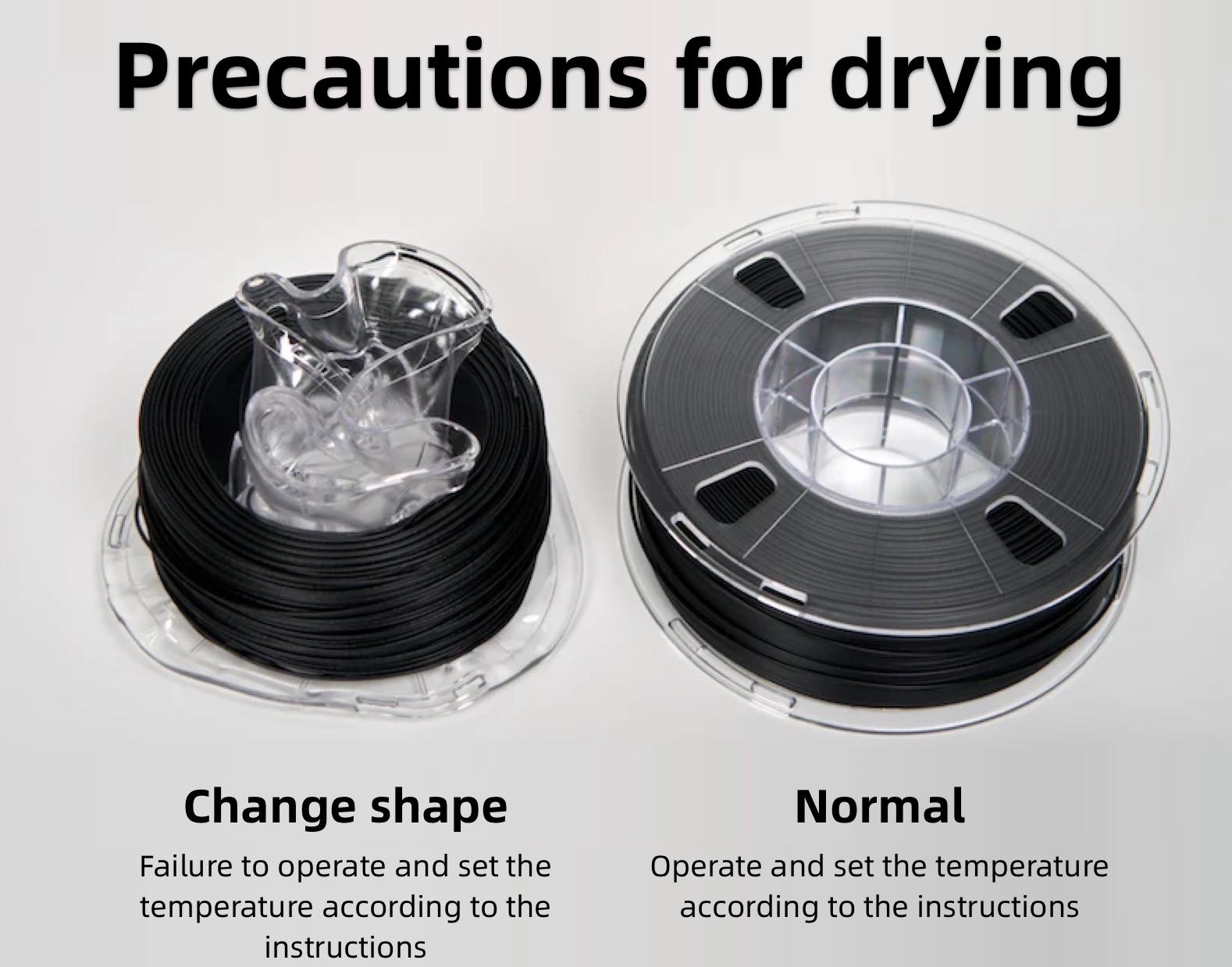

| Drying Parameters |

• PTC Small Drying Box: 60-70°C, dry for 4-6 hours. • Small Constant Temperature Drum Dryer: Reduce the temperature by 20°C to avoid uneven temperature distribution in small equipment causing deformation (40-45°C, dry for 4 hours). If printing results do not improve after this drying, use an empty material tray to test the temperature and then increase the drying temperature as needed to prevent deformation from excessive or uneven heating. • Large Constant Temperature Drum Dryer: 60-70°C, dry for 4-6 hours. Note: Why are the drying temperatures different for various drying equipment? Click here to learn more. |

|

Precautions ⚠️ |

1. If unsure, first conduct a temperature test using an empty spool to avoid overheating or uneven heating that may lead to spool deformation. 2. Strictly follow the drying temperature and time recommended on the material parameter introduction page. 3. It is recommended to use a drum-type drying box (do not place the spool directly in front of the air outlet, as this may cause deformation). 4. When drying spools, avoid positioning them near the air outlet. 5. It is not recommended to place the spool directly on a mesh rack (use flat surfaces such as metal plates instead). 6. Be cautious of high temperatures when removing materials to avoid burns. 7. Prevent fire hazards by ensuring the safe use of equipment. 8. For drying materials, printed parts, and annealing, it is recommended to use equipment with even temperature distribution, such as a blast drying oven (ensure it is from a reliable manufacturer, as some may be inadequate for use). Do not use microwave ovens or household ovens, and avoid placing items in areas with uneven heating or excessive force, as this could cause local damage or deformation.

|

| The impact of moisture absorption on 3D printing filament |

|

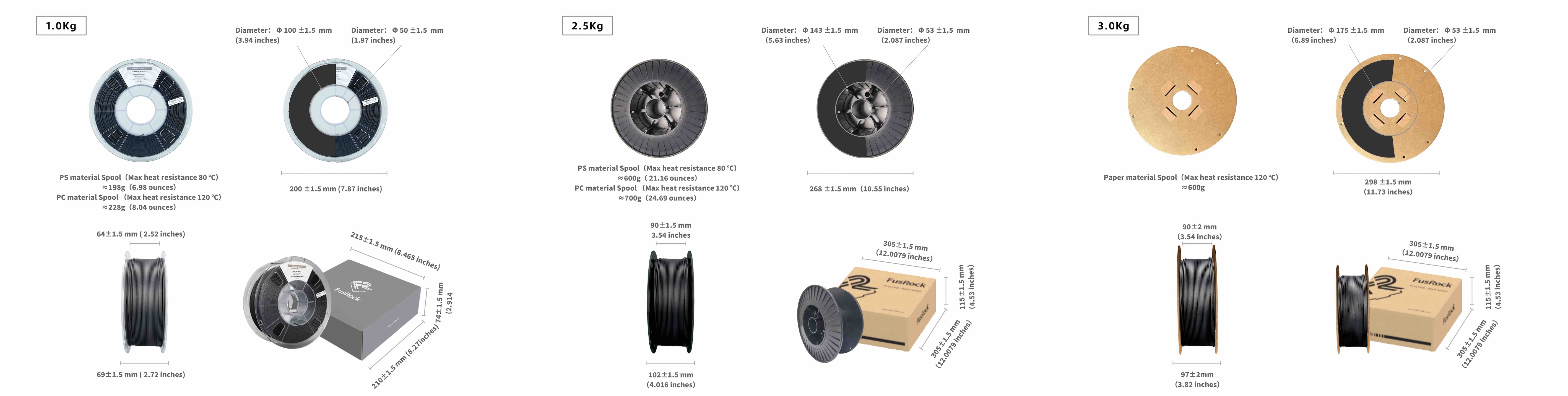

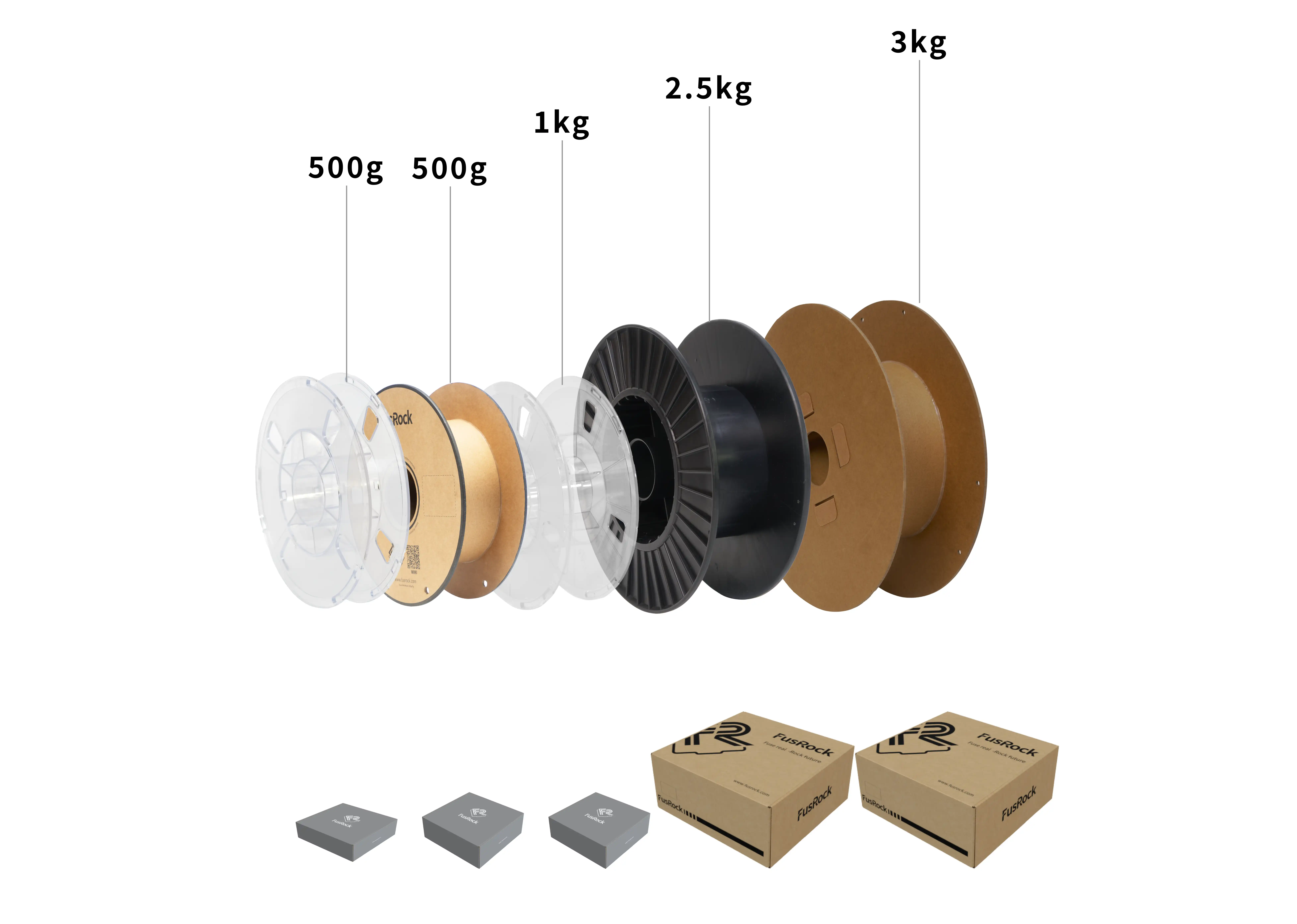

¶ Common Tray Sizes, Net Weight, and Specification Information

| Spool material | The material of the plastic filament spool is PS (Polystyrene) with a temperature resistance of 80°C. (Please note that the temperature resistance of the spool refers to the maximum temperature it can withstand. It is not the same as the drying temperature. The drying temperature should follow the guidelines outlined in the “Moisture Treatment Plan and Methods for Filaments.”) |

| Plastic spool size specifications |

|

| Product Packaging Instructions |

Double-sided Aluminum Foil Bag: Provides efficient moisture protection, with a moisture content of < 0.06% at the time of shipment, offering better water resistance than transparent nylon bags. Built-in Seal Strip: The heat-sealed opening can be reopened and reused, extending the dry state of the material. It can also be used as a storage bag, making it more environmentally friendly. |

¶ Common 3D Printers and Related Auxiliary Equipment Compatibility Guide

| 3D Printer Compatibility List | BambuLab Equipment Compatibility |

H2D\X1 Carbon\X 1\P1P\P1S\ • Ensure smooth filament feeding. It is recommended to use a moisture-proof box with bearings and PTFE tubing for feeding. • Supports hardened steel nozzles or higher hardness materials. • No need for enclosure printing. • Supports AMS/AMS2; ensure moisture control. • Avoid external metal brackets that could interfere or cause moisture absorption. A1/A1 mini • Ensure smooth filament feeding. It is recommended to use a moisture-proof box with bearings and PTFE tubing for feeding. • Supports hardened steel nozzles or higher hardness materials. • No need for enclosure printing. • Supports AMS Lite series (not recommended). • Ensure moisture control. • Avoid external metal brackets that could interfere or cause moisture absorption. Other models - Pending update. |

| Raise3D Equipment Compatibility |

Pro3 / Pro3 Plus • Ensure smooth filament feeding. It is recommended to use a moisture-proof box with bearings and PTFE tubing for feeding. • Supports hardened steel nozzles or higher hardness materials. • No need for enclosure printing. • Ensure moisture control. • Avoid external metal brackets that could interfere or cause moisture absorption. E2 / E2-CF • No need for enclosure printing. • Ensure filament moisture control. Other models - Pending update. |

|

| Creality Equipment Compatibility |

K1 / K1C / K1Max • Ensure smooth filament feeding and adjust the feeding tube angle if necessary. • It is recommended to use a moisture-proof box with bearings and PTFE tubing for feeding. • Supports hardened steel nozzles or higher hardness materials. • No need for enclosure printing. • Ensure moisture control. • Avoid external metal brackets that could interfere or cause moisture absorption. Other models - Pending update. |

|

| Prusa 3D Equipment Compatibility |

Prusa XL • Ensure smooth filament feeding and adjust the feeding tube angle if necessary. • It is recommended to use a moisture-proof box with bearings and PTFE tubing for feeding. • Supports hardened steel nozzles or higher hardness materials. • No need for enclosure printing. • Ensure moisture control. • Avoid external metal brackets that could interfere or cause moisture absorption. Other models - Pending update. |

|

| FlashForge Equipment Compatibility |

AD5M • Ensure smooth filament feeding and adjust the feeding tube angle if necessary. • It is recommended to use a moisture-proof box with bearings and PTFE tubing for feeding. • Supports hardened steel nozzles or higher hardness materials. • No need for enclosure printing. • Ensure moisture control. • Avoid external metal brackets that could interfere or cause moisture absorption. Other models - Pending update. |

|

| QiDi Equipment Compatibility |

X-Max 3 / Q1 Pro / X-Plus 3 / X-Plus 4 • Ensure smooth filament feeding and adjust the feeding tube angle if necessary. • It is recommended to use a moisture-proof box with bearings and PTFE tubing for feeding. • Supports hardened steel nozzles or higher hardness materials. • No need for enclosure printing. • Ensure moisture control. • Avoid external metal brackets that could interfere or cause moisture absorption. Other models - Pending update. |

|

| For more supported models and detailed descriptions, please contact us at [email protected]. | ||

¶ Frequently Asked Questions

¶ We look forward to your questions~

¶ Customer Case Analysis: Common Issues Encountered

¶ We invite you to share your experiences!

¶ Health Tips — Caring for Your Health: FusRock Recommends You

1. For long-term and extensive use of 3D printing materials, it is recommended to operate in a dedicated room with proper ventilation.

2. If you have a history of allergies, make sure that the material you are using will not cause any allergic reactions upon contact.

3. For individuals with respiratory conditions or chronic illnesses, please wear a mask to protect your health. Even if you do not have any related conditions, it is strongly recommended to wear a mask during operation.

4. When sanding, cutting, or performing other actions on fiber-based printed products, which may release fibers, be sure to take protective measures to prevent injury or inhalation.

5. Lastly, we recommend keeping children and infants away from the printing area during operations to ensure a safe environment for the next generation.

¶ Application Disclaimer

1. Fusrock 3D printing filaments are intended for general-purpose use and have been tested under standard conditions. However, the performance and safety of printed objects may be affected by various factors, including printing parameters, model design, usage environment, and specific application scenarios.

2. By using Fusrock materials, the user acknowledges and agrees to independently assess whether the printed parts are suitable for their intended use and assumes all associated risks.

3. Fusrock shall not be held liable for any damage, injury, or loss resulting from the use of printed products made with our materials, including but not limited to structural failure, functional defects, or safety hazards in actual application environments. Users must conduct adequate testing before using printed parts in any critical, functional, or commercial context. Except for the certifications explicitly stated for specific Fusrock materials, Fusrock products are not certified for use in medical, aerospace, or life-support applications.

¶ Disclaimer and Copyright

Thank you for visiting our website! Before using this site, please carefully read the following copyright statement and terms of use:

Copyright Statement:

1. All content on this website, including but not limited to text, images, graphics, audio, video, software, its compilation, code, and technical architecture (collectively referred to as “content”), is owned by this website or its respective rights holders and is protected by the Copyright Law of the People’s Republic of China and other applicable laws and regulations.

2. Without written authorization from this website, no entity or individual may copy, reproduce, distribute, modify, display, perform, mirror, upload, download, or use the content of this website in any other way.

3. Third-party content referenced on this website remains the property of its original rights holders. If your legal rights have been infringed for reasons unrelated to this website, please contact us promptly, and we will address it as soon as verified.

Terms of Use:

1. You may browse, download, or print content from this website for non-commercial purposes, provided you comply with relevant laws and this statement, and retain all copyright notices and ownership information without modification.

2. Commercial use of the content or services on this website is prohibited, including but not limited to creating derivative works, selling, or distributing the content to third parties.

3. The use of automated tools (such as crawlers, robots, etc.) to obtain, copy, monitor, or attempt to access the content or data of this website is prohibited.

Disclaimer:

1. While this website strives to provide accurate and reliable information, we make no express or implied guarantees regarding the completeness, timeliness, or accuracy of the content.

2. This website assumes no legal responsibility for any direct or indirect losses arising from the use of its content or services.

3. This website may contain links to third-party websites, but we do not take responsibility for the content or actions of third-party sites.

Rights Protection:

If you violate this statement and infringe upon the legal rights of this website, we reserve the right to take legal action, including but not limited to filing a lawsuit or taking other legal measures.

If you have any questions about this statement, please contact us at [[email protected]].

The final interpretation of this statement is reserved by this website.